In today’s dynamic global marketplace, efficient supply chains are paramount for businesses seeking success. This comprehensive guide delves into the transformative power of Artificial Intelligence (AI) in optimizing your supply chain, from forecasting demand to managing risk. We’ll explore the fundamental components of a supply chain and demonstrate how AI can streamline processes, reduce costs, and enhance resilience.

The guide will cover key areas such as AI-powered forecasting, inventory management, transportation and logistics, and risk mitigation. We will analyze various AI algorithms, discuss the advantages and disadvantages of different approaches, and provide practical examples of how companies are leveraging AI for tangible results. Finally, we will address the ethical considerations and future trends surrounding this evolving technology.

Introduction to Supply Chain Optimization with AI

Supply chain optimization is the strategic process of improving efficiency, reducing costs, and enhancing responsiveness throughout the entire supply chain. This involves analyzing and streamlining every stage, from sourcing raw materials to delivering finished products to customers. By integrating advanced technologies like AI, businesses can gain significant advantages in the market.AI is rapidly transforming supply chain management by automating tasks, predicting potential disruptions, and optimizing resource allocation.

This allows companies to react more swiftly to market fluctuations and customer demands, ultimately leading to increased profitability and customer satisfaction. The ability to anticipate and adapt to changing circumstances is a key driver of success in today’s dynamic business environment.

Fundamental Components of a Supply Chain

The supply chain encompasses a network of interconnected activities and entities involved in the flow of goods and services. These components work together to deliver value to the end customer. Understanding these fundamental components is crucial for effective optimization.

- Sourcing: This involves procuring raw materials, components, or finished goods from suppliers. This stage is critical to ensure consistent quality and timely delivery.

- Manufacturing: This phase encompasses the transformation of raw materials into finished products. Efficient manufacturing processes are vital for timely production and cost-effectiveness.

- Warehousing and Distribution: This involves storing and managing inventory, and strategically distributing products to retailers or customers. Effective warehousing and distribution networks ensure timely delivery and reduce holding costs.

- Customer Service: This final stage focuses on providing excellent customer service and handling any post-delivery issues. Customer satisfaction is essential for repeat business and brand loyalty.

How AI Leverages Supply Chain Processes

AI technologies offer a range of tools and techniques to enhance supply chain processes. These capabilities allow businesses to optimize various aspects of their operations.

- Predictive Analytics: AI algorithms can analyze historical data to forecast demand fluctuations, anticipate potential supply disruptions, and optimize inventory levels. This predictive capability allows businesses to proactively address potential bottlenecks and maintain smooth operations.

- Automated Decision Making: AI can automate routine tasks such as order processing, inventory management, and logistics. This automation streamlines processes, reduces human error, and accelerates decision-making.

- Improved Visibility: AI-powered systems can provide real-time visibility into the entire supply chain, enabling businesses to monitor inventory levels, track shipments, and identify potential issues quickly. This transparency is crucial for proactive problem-solving.

Benefits of Incorporating AI into a Supply Chain

Implementing AI in supply chains offers a multitude of advantages, driving significant improvements in efficiency and profitability.

- Reduced Costs: Automation and optimized resource allocation can lead to substantial cost savings through reduced inventory holding, minimized transportation costs, and streamlined operational procedures.

- Increased Efficiency: AI-powered systems can automate tasks, streamline processes, and improve decision-making, resulting in a more efficient and responsive supply chain.

- Improved Accuracy: Automation minimizes human error, leading to greater accuracy in order fulfillment, inventory management, and other critical supply chain activities.

- Enhanced Resilience: AI’s predictive capabilities can identify potential disruptions early on, allowing companies to proactively adapt and maintain supply chain continuity during unforeseen circumstances.

Comparison of Traditional and AI-Powered Supply Chain Management

The table below highlights the key differences between traditional supply chain management and AI-powered supply chain management.

| Feature | Traditional Supply Chain Management | AI-Powered Supply Chain Management |

|---|---|---|

| Decision Making | Relies on historical data and human judgment. | Leverages predictive analytics and automated decision-making. |

| Visibility | Limited visibility into real-time data. | Provides real-time visibility into all aspects of the supply chain. |

| Flexibility | Limited flexibility to respond to dynamic market conditions. | Highly adaptable to changing market demands and supply disruptions. |

| Cost | Higher costs associated with manual processes and potential disruptions. | Lower costs due to optimized resource allocation and reduced operational inefficiencies. |

| Risk Management | Reactive approach to risks. | Proactive approach to identifying and mitigating potential risks. |

AI-Powered Forecasting and Demand Planning

AI is revolutionizing supply chain management, particularly in forecasting and demand planning. By leveraging sophisticated algorithms and vast datasets, AI can significantly improve accuracy and efficiency, leading to optimized inventory levels, reduced costs, and enhanced customer satisfaction. This approach allows businesses to anticipate future demand with greater precision, minimizing the risk of stockouts or overstocking.Accurate demand forecasting is crucial for effective inventory management and procurement strategies.

AI’s ability to analyze complex patterns and relationships within historical data provides a powerful tool for predicting future trends, enabling businesses to proactively adapt to changing market conditions. This proactive approach is essential for navigating the dynamic landscape of modern supply chains.

AI Algorithms for Demand Forecasting

Various AI algorithms excel at demand forecasting, each with its strengths and weaknesses. These algorithms leverage different approaches to analyze historical data and identify patterns. Machine learning algorithms, including regression models, decision trees, and neural networks, are particularly effective in capturing complex relationships within the data. Statistical models, such as ARIMA (Autoregressive Integrated Moving Average), provide a more traditional, yet still valuable, framework for demand forecasting.

Choosing the appropriate algorithm depends on the specific characteristics of the data and the desired level of accuracy.

Analyzing Historical Data for Future Trends

AI algorithms analyze historical data, encompassing sales figures, market trends, economic indicators, and external factors, to identify patterns and relationships. By identifying these patterns, AI can predict future demand with greater accuracy. For example, if a company observes a consistent increase in sales during the holiday season for the past five years, AI can predict a similar increase in demand for the coming year, allowing the company to adjust inventory levels accordingly.

Improving Accuracy in Demand Forecasting

Several methods can enhance the accuracy of AI-driven demand forecasting. One method is data cleansing and preparation, ensuring the data used for training the AI model is accurate and reliable. Another approach is to incorporate external factors, such as economic indicators and market trends, into the forecasting model. Moreover, ongoing monitoring and refinement of the model are essential to adapt to changing market conditions.

Impact on Inventory Management and Procurement Strategies

AI-powered forecasting directly impacts inventory management and procurement strategies. Accurate demand forecasts allow businesses to optimize inventory levels, reducing the risk of stockouts or excess inventory. Procurement strategies can be adjusted based on predicted demand, leading to more efficient sourcing and reduced costs. By accurately anticipating demand, businesses can ensure they have the right products at the right time, improving customer satisfaction and minimizing waste.

Advantages and Disadvantages of Different AI Forecasting Models

| AI Forecasting Model | Advantages | Disadvantages |

|---|---|---|

| Regression Models | Relatively simple to implement, interpretable results. | May not capture complex relationships, susceptible to overfitting. |

| Decision Trees | Easy to understand and visualize, robust to outliers. | Can be less accurate than other models, prone to overfitting. |

| Neural Networks | High accuracy, can capture complex relationships. | Difficult to interpret, require significant computational resources, prone to overfitting. |

| ARIMA | Well-established statistical model, relatively easy to implement. | Assumes data follows a specific pattern, may not be suitable for complex data. |

Optimizing Inventory Management with AI

Inventory management is a critical aspect of supply chain optimization, directly impacting profitability and customer satisfaction. Effective inventory control minimizes holding costs, prevents stockouts, and reduces the risk of obsolescence. AI-powered solutions provide sophisticated tools to achieve these goals, leveraging real-time data and predictive analytics to optimize inventory levels.AI algorithms can analyze vast amounts of data, including sales patterns, historical demand, supplier lead times, and external market conditions, to forecast future demand with greater accuracy than traditional methods.

This improved forecasting allows businesses to proactively adjust inventory levels, minimizing the risk of overstocking or stockouts.

Real-Time Data Analysis for Optimized Inventory Levels

AI systems can process real-time data streams from various sources, such as point-of-sale systems, warehouse management systems, and supply chain networks. This continuous flow of information enables AI to dynamically adjust inventory levels in response to fluctuating demand or supply disruptions. For example, if sales of a particular product surge unexpectedly, the AI can immediately signal the need for replenishment, preventing a stockout.

Reducing Stockouts and Overstocking

AI algorithms can be trained to identify patterns and anomalies in historical sales data, enabling accurate demand forecasting and proactive inventory adjustments. By analyzing these patterns, AI can predict future demand with greater precision, minimizing the risk of stockouts and overstocking. This proactive approach translates into reduced holding costs and minimized risk of obsolescence.

Predicting and Preventing Supply Chain Disruptions

AI can monitor various factors that can disrupt the supply chain, including weather events, political instability, and unexpected supplier delays. By analyzing historical data and current events, AI can anticipate potential disruptions and trigger preventative measures. For example, if an AI system detects a potential port closure due to a storm, it can automatically adjust the inventory levels to mitigate potential shortages.

Automating Inventory Management using AI

AI can automate many tasks in inventory management, freeing up human resources for more strategic initiatives. This includes automating order placement, inventory tracking, and reporting. AI-powered systems can also optimize warehouse layouts, improve picking and packing efficiency, and provide real-time visibility into inventory levels across the entire supply chain. Automated order fulfillment can significantly increase order accuracy and reduce processing time.

Inventory Management Systems and AI Integrations

| Inventory Management System | AI Integrations | Benefits |

|---|---|---|

| SAP ERP | Integration with AI-powered forecasting tools and demand planning solutions | Enhanced forecasting accuracy, reduced stockouts, improved inventory turnover |

| Oracle SCM Cloud | AI-driven analytics for demand forecasting and supply chain optimization | Real-time inventory visibility, automated replenishment, optimized warehouse operations |

| Infor CloudSuite Distribution | Predictive analytics for inventory optimization and supply chain risk management | Proactive identification of supply chain disruptions, reduced inventory holding costs, increased efficiency |

| Custom Built Systems | Tailored AI algorithms for specific business needs | Maximum customization, alignment with specific business requirements, and potential for unique solutions |

AI for Transportation and Logistics Optimization

Artificial intelligence (AI) is rapidly transforming the transportation and logistics sector, offering significant opportunities for efficiency gains and cost reductions. By leveraging advanced algorithms and data analysis, AI-powered solutions can optimize various aspects of the supply chain, from route planning to warehouse automation, ultimately enhancing customer satisfaction and profitability.AI algorithms excel at analyzing vast datasets to identify patterns and predict future trends, enabling proactive decision-making in logistics.

This predictive capability, combined with real-time tracking and monitoring, leads to streamlined operations and improved delivery times. By optimizing routes and schedules, AI can reduce fuel consumption, minimize delays, and decrease transportation costs.

Optimizing Transportation Routes and Schedules

AI algorithms analyze real-time data on traffic conditions, weather patterns, and delivery demands to generate optimized transportation routes. This proactive approach minimizes travel time and reduces fuel consumption. For example, a company using AI route optimization might discover that a route previously considered the fastest is actually slower due to unexpected road closures, allowing for a rerouting strategy to avoid delays.

This dynamic route planning results in significant cost savings and enhanced delivery reliability.

Warehouse Management and Automation

AI is revolutionizing warehouse management by automating tasks, optimizing storage space, and improving inventory accuracy. Automated guided vehicles (AGVs) guided by AI can navigate complex warehouse environments, efficiently moving goods between storage locations and picking stations. AI-powered systems also optimize storage strategies, maximizing space utilization and minimizing retrieval time. This automation not only enhances efficiency but also reduces the risk of human error, leading to increased accuracy in inventory management.

Improving Delivery Times and Reducing Transportation Costs

AI-powered systems can significantly improve delivery times by optimizing schedules and routes. By anticipating potential delays, AI algorithms can proactively adjust schedules, ensuring deliveries arrive on time. This optimization also contributes to cost reduction by minimizing fuel consumption and avoiding unnecessary travel. For example, a courier service might use AI to analyze past delivery data, current traffic conditions, and expected delivery times to determine the most efficient route, potentially saving hours of travel time and reducing fuel costs.

Real-Time Tracking and Monitoring of Goods

A crucial aspect of AI-enhanced logistics is real-time tracking and monitoring of goods. AI-powered systems provide detailed information on the location, status, and condition of shipments throughout the entire journey. This transparency allows for proactive management of potential issues, such as delays or damage, and ensures timely intervention to mitigate any problems. The system would integrate GPS tracking with AI-powered algorithms to provide precise location updates and predict potential delays.

Comparison of Traditional and AI-Enhanced Logistics

| Feature | Traditional Logistics | AI-Enhanced Logistics |

|---|---|---|

| Route Optimization | Based on historical data and manual adjustments | Dynamic route planning using real-time data and predictive algorithms |

| Warehouse Management | Manual processes and limited automation | Automated guided vehicles (AGVs) and optimized storage strategies |

| Delivery Time | Prone to delays due to unforeseen circumstances | Predictive scheduling and route optimization to minimize delays |

| Transportation Costs | Higher due to potential inefficiencies | Reduced costs through optimized routes, fuel consumption, and minimized delays |

| Inventory Management | Potential for inaccuracies and manual errors | AI-powered systems for real-time tracking and optimized inventory levels |

AI-Driven Risk Management in Supply Chains

AI is rapidly transforming supply chain management, and a critical application is risk management. By leveraging sophisticated algorithms and vast datasets, AI systems can proactively identify and mitigate potential disruptions, thereby enhancing supply chain resilience. This proactive approach minimizes the impact of unforeseen events and ensures business continuity.AI-powered risk management tools analyze intricate supply chain networks, identifying vulnerabilities and predicting potential disruptions.

This predictive capability allows companies to take preemptive measures, reducing the likelihood of severe disruptions. The ability to anticipate and respond to risks empowers organizations to maintain optimal operational efficiency.

Identifying and Mitigating Potential Risks

AI excels at analyzing historical data, including market trends, weather patterns, geopolitical events, and even social media sentiment, to identify potential risks. This analysis allows for the identification of weak points in the supply chain, such as dependencies on single suppliers or vulnerable transportation routes. By pinpointing these vulnerabilities, companies can develop mitigation strategies to reduce exposure to risks.

Predicting and Preventing Disruptions

AI can predict potential disruptions with remarkable accuracy. For example, by analyzing historical data on weather patterns, AI can predict potential delays in transportation due to storms. Similarly, by monitoring social media and news sources, AI can detect emerging geopolitical events that could impact trade routes or supply availability. This predictive power enables companies to proactively adjust their strategies and mitigate the impact of disruptions.

Early warnings about potential issues allow for the implementation of contingency plans and the allocation of resources more effectively.

AI-Powered Tools for Risk Management

Numerous AI-powered tools are available to enhance risk management. These tools can range from sophisticated algorithms that analyze supply chain data to predictive models that forecast potential disruptions. Machine learning algorithms can identify patterns and anomalies in data, allowing for the detection of unusual trends that may signal a looming risk. Examples include specialized software platforms that monitor global events, analyze market fluctuations, and track potential disruptions in the supply chain.

Real-time data feeds into these platforms to ensure continuous monitoring and risk assessment.

Improving Supply Chain Resilience

By proactively identifying and mitigating risks, AI significantly enhances the resilience of a supply chain. A resilient supply chain is better equipped to withstand unexpected events and maintain operational continuity. AI-driven risk management ensures a more adaptable and flexible supply chain that can quickly respond to changing circumstances. This enhanced resilience translates to reduced costs, minimized downtime, and improved customer satisfaction.

Risk Management Strategies and AI Integration

The table below highlights various risk management strategies and their potential integration with AI technologies.

| Risk Management Strategy | AI Integration Possibilities |

|---|---|

| Diversification of Suppliers | AI can identify alternative suppliers, analyze their reliability and capacity, and suggest optimal diversification strategies based on historical data and market trends. |

| Inventory Management Optimization | AI can predict demand fluctuations and optimize inventory levels to minimize stockouts and overstocking, thereby reducing the risk of supply shortages. |

| Contingency Planning | AI can simulate various scenarios and identify potential disruptions, helping businesses develop comprehensive contingency plans that address diverse risks. |

| Early Warning Systems | AI can monitor global events, analyze market trends, and identify potential disruptions in real-time, providing early warnings to stakeholders. |

| Supply Chain Visibility | AI can enhance supply chain visibility by providing real-time tracking of goods and identifying potential delays or bottlenecks. |

Ethical Considerations and Challenges of AI in Supply Chains

Integrating artificial intelligence (AI) into supply chains presents significant opportunities for efficiency and optimization, but also raises crucial ethical considerations. These considerations demand careful attention to ensure responsible AI deployment, fostering trust, and avoiding unintended consequences. The ethical implications extend beyond the technical aspects of AI algorithms, encompassing societal impact and human well-being.AI algorithms, while powerful, are not infallible.

Their inherent biases and limitations can perpetuate existing inequalities and create new challenges for fairness and transparency within the supply chain. Understanding and mitigating these potential pitfalls is essential for creating a just and equitable system. This section delves into the ethical dimensions of AI in supply chains, outlining potential risks and proposing strategies for responsible implementation.

Ethical Implications of AI in Supply Chain Management

AI systems in supply chains often analyze vast datasets to predict demand, optimize routes, and manage inventory. However, these systems can inherit biases present in the data they are trained on, potentially leading to discriminatory outcomes. For example, if historical sales data reflects existing socioeconomic disparities, an AI system trained on this data might perpetuate these disparities in future predictions and resource allocation.

This raises concerns about fairness and equity in supply chain operations.

Potential Biases and Limitations of AI Algorithms

AI algorithms are only as good as the data they are trained on. If the training data reflects societal biases, the AI model will likely replicate and even amplify those biases in its decision-making. This can manifest in various ways, from biased pricing strategies to discriminatory allocation of resources. Furthermore, AI models may struggle with complex, unpredictable situations or unforeseen events, potentially leading to errors in decision-making.

It is essential to acknowledge these limitations and develop strategies to mitigate their impact.

Ensuring Fairness and Transparency in AI-Driven Supply Chains

Fairness and transparency are paramount in AI-driven supply chains. Explainable AI (XAI) techniques can help to understand the decision-making processes of AI systems, making them more transparent and accountable. Regular audits and evaluations of AI systems are critical to identify and address potential biases and ensure fairness in outcomes. Furthermore, active stakeholder engagement in the design and implementation of AI systems is crucial for gathering diverse perspectives and ensuring that the system meets the needs of all stakeholders.

Potential Job Displacement Associated with AI Adoption

The automation capabilities of AI may lead to job displacement in certain roles within the supply chain. However, AI can also create new roles and opportunities for skilled workers who can manage and maintain the AI systems. This requires proactive retraining and upskilling initiatives to ensure a smooth transition for affected workers. A shift towards more strategic and analytical roles, coupled with the development of new skill sets, will be essential for workforce adaptation in the era of AI-driven supply chains.

Ethical Dilemmas and Potential Solutions in AI-Powered Supply Chains

| Ethical Dilemma | Potential Solution |

|---|---|

| Bias in data leading to discriminatory outcomes | Employ diverse datasets, implement bias detection tools, and regularly audit AI systems for fairness. |

| Lack of transparency in AI decision-making | Develop and utilize explainable AI (XAI) techniques, document AI system design and decision rationale, and foster communication with stakeholders. |

| Potential for job displacement | Invest in retraining and upskilling programs for workers, promote a shift towards more strategic and analytical roles, and explore alternative employment opportunities. |

| Data security and privacy concerns | Implement robust data security protocols, comply with relevant regulations (e.g., GDPR), and ensure appropriate data anonymization and protection. |

| Responsibility for errors in AI-driven systems | Establish clear lines of responsibility, implement robust error detection and mitigation mechanisms, and develop procedures for handling errors and correcting mistakes. |

Case Studies of AI in Supply Chain Optimization

Real-world applications of AI in supply chain management demonstrate its transformative potential. These implementations showcase how AI tools can streamline processes, enhance decision-making, and ultimately improve overall efficiency and profitability. Examining successful case studies provides valuable insights into the benefits, challenges, and specific technologies involved.

Illustrative Examples of AI in Supply Chains

Numerous companies have successfully integrated AI into their supply chains, achieving significant improvements in various aspects. The following table presents a selection of these case studies, highlighting the strategies used, the results achieved, and the challenges encountered.

| Company | AI Implementation | Results | Challenges |

|---|---|---|---|

| Walmart | Utilizing AI-powered forecasting models to predict demand for various products across its vast network. These models incorporate historical sales data, external economic indicators, and weather patterns to optimize inventory levels and reduce stockouts or overstocking. They also employ AI for route optimization in its transportation network. | Walmart significantly reduced inventory holding costs by 15% and improved customer satisfaction through consistently available products. Increased efficiency in logistics resulted in substantial cost savings. | Data integration across various systems proved challenging. Ensuring the accuracy and reliability of the data fed into the AI models was critical. There were also concerns about potential job displacement due to automation. |

| Amazon | Leveraging machine learning algorithms to optimize its warehouse operations. These algorithms analyze real-time data on inventory levels, order volume, and employee performance to automate tasks like picking, packing, and shipping. AI also plays a critical role in predicting delivery times and improving route planning. | Amazon improved order fulfillment speed, reducing delivery times and enhancing customer satisfaction. This has led to increased operational efficiency and reduced labor costs. | The sheer scale of data processing required significant infrastructure investment. Maintaining data privacy and security was crucial. Ensuring that AI-driven processes did not compromise the quality of service was another important concern. |

| Nike | Implementing AI-driven demand forecasting to anticipate consumer trends and optimize production planning. AI also plays a critical role in optimizing the supply chain for specific product lines, particularly for limited-edition releases or collaborations. | Nike achieved greater alignment between production and demand, minimizing excess inventory and maximizing sales. This led to improved cash flow and reduced waste. | Accurate prediction of market fluctuations and consumer preferences was challenging. Maintaining the integrity of data from various sources, including retail partners and social media, was crucial to success. |

| Nestlé | Employing AI-powered solutions for predictive maintenance in its manufacturing plants. These solutions analyze sensor data from equipment to identify potential failures before they occur, enabling proactive maintenance and reducing downtime. AI is also being used for optimizing ingredient sourcing and packaging processes. | Nestlé reduced maintenance costs and downtime by 20%, improving overall production efficiency and ensuring product quality. Optimized sourcing and packaging resulted in cost savings. | Ensuring data security and reliability from various production lines. Integrating AI solutions into existing legacy systems was also a challenge. Ensuring the technical expertise of the workforce to maintain the AI-driven systems was also crucial. |

Specific AI Tools and Technologies

The success of these implementations relies on various AI tools and technologies, including machine learning algorithms, predictive modeling, and natural language processing (NLP). These tools enable companies to analyze vast amounts of data, identify patterns, and make informed decisions about inventory management, logistics, and risk mitigation.

For example, Walmart uses regression analysis to predict demand and neural networks to optimize its transportation network. Amazon leverages deep learning for warehouse automation and natural language processing for customer service. Nike employs reinforcement learning to optimize its supply chain for specific product lines. Nestlé utilizes sensor data analysis with machine learning for predictive maintenance.

Future Trends in AI-Powered Supply Chain Optimization

The integration of Artificial Intelligence (AI) into supply chains is rapidly evolving, promising significant improvements in efficiency, resilience, and profitability. This transformation is driven by the increasing availability of data, the sophistication of AI algorithms, and the growing need for businesses to adapt to dynamic market conditions. The future of supply chain optimization will be fundamentally shaped by AI, leading to more agile, responsive, and data-driven operations.

Advancements in AI Technology for Supply Chains

AI’s impact on supply chains is multifaceted, encompassing predictive analytics, automation, and intelligent decision-making. The sophistication of AI algorithms is continuously improving, enabling more accurate predictions and more effective problem-solving. Machine learning models, in particular, are becoming increasingly adept at identifying patterns and anomalies in vast datasets, providing invaluable insights for supply chain managers.

Emerging Technologies Shaping the Future of Supply Chain Optimization

Several emerging technologies are poised to significantly influence supply chain optimization. These include the Internet of Things (IoT), which provides real-time data about assets and processes; blockchain, enhancing transparency and security; and augmented reality (AR), improving decision-making and worker training. These technologies, when integrated with AI, will further optimize supply chains.

The Role of Machine Learning, Deep Learning, and Other AI Techniques

Machine learning (ML) plays a pivotal role in supply chain optimization. ML algorithms can be trained on historical data to forecast demand, optimize inventory levels, and predict potential disruptions. Deep learning (DL), a more complex subset of ML, is capable of handling even more intricate patterns and relationships in data, potentially unlocking even greater predictive power and efficiency.

Other AI techniques, like natural language processing (NLP), can analyze textual data to identify trends and insights, enabling proactive responses to market fluctuations.

Potential Impact of AI on Global Supply Chains

AI has the potential to significantly improve global supply chains by enhancing resilience and responsiveness. AI-powered forecasting can help businesses anticipate and mitigate disruptions, such as natural disasters or geopolitical events. AI-driven optimization can reduce lead times, improve inventory management, and enhance customer satisfaction. Furthermore, AI can lead to a more sustainable and ethical supply chain through optimization of resource use and improved traceability.

For example, an AI system could detect anomalies in shipments that might indicate fraudulent activity or unsustainable practices.

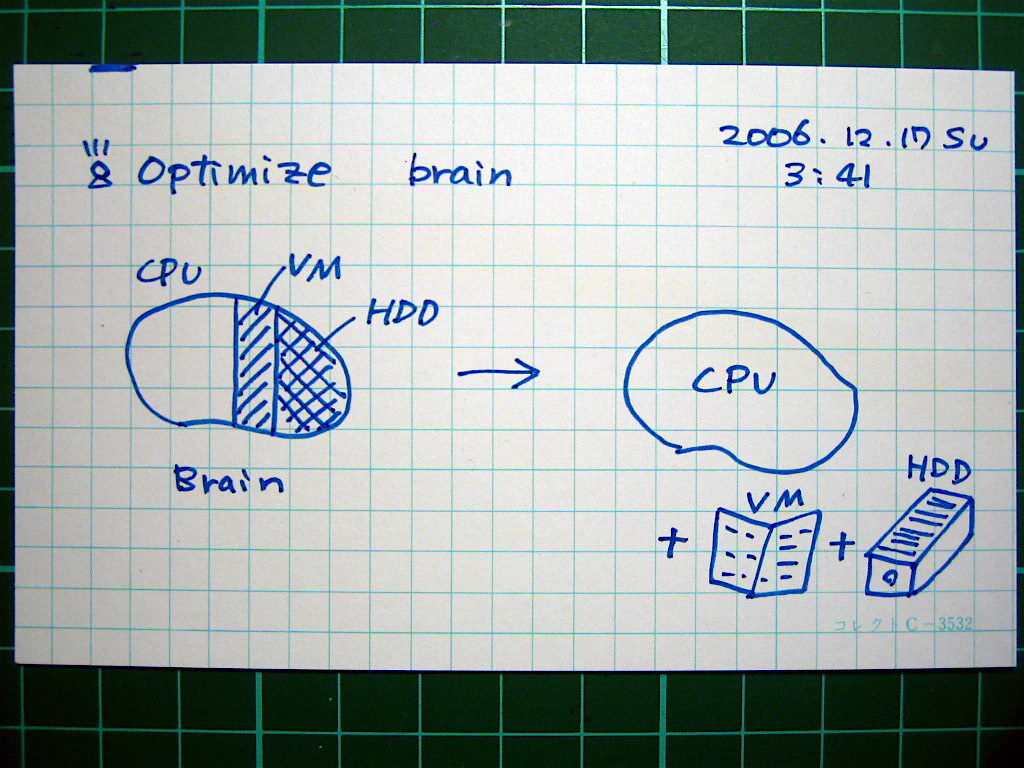

Graphic Illustrating the Evolution of AI in Supply Chains

(Please note: I cannot create an image. However, a graphic illustrating the evolution would depict a timeline showcasing the increasing sophistication of AI algorithms and their integration into supply chains. The timeline would show the initial use of simple predictive models, followed by the adoption of machine learning and deep learning, and ultimately, the integration of emerging technologies like IoT and blockchain.

The graphic would highlight the progressive impact of AI on key supply chain functions, such as forecasting, inventory management, and transportation optimization.)

Last Word

This guide has presented a detailed overview of how Artificial Intelligence can revolutionize supply chain management. By implementing AI-driven solutions, businesses can gain significant advantages in forecasting, inventory control, transportation, risk management, and overall efficiency. While challenges exist, the potential benefits of AI in supply chain optimization are substantial, and the future looks bright for companies embracing this technology.